A whole-home standby generator is a small engine that works hard when you need it most. Like any engine, it relies on precise mechanical timing to run efficiently and reliably. One of the most important, and most overlooked, maintenance items is a valve adjustment. When was the last time your valves were adjusted? If you don't know, give us a call!

What Is a Valve Adjustment?

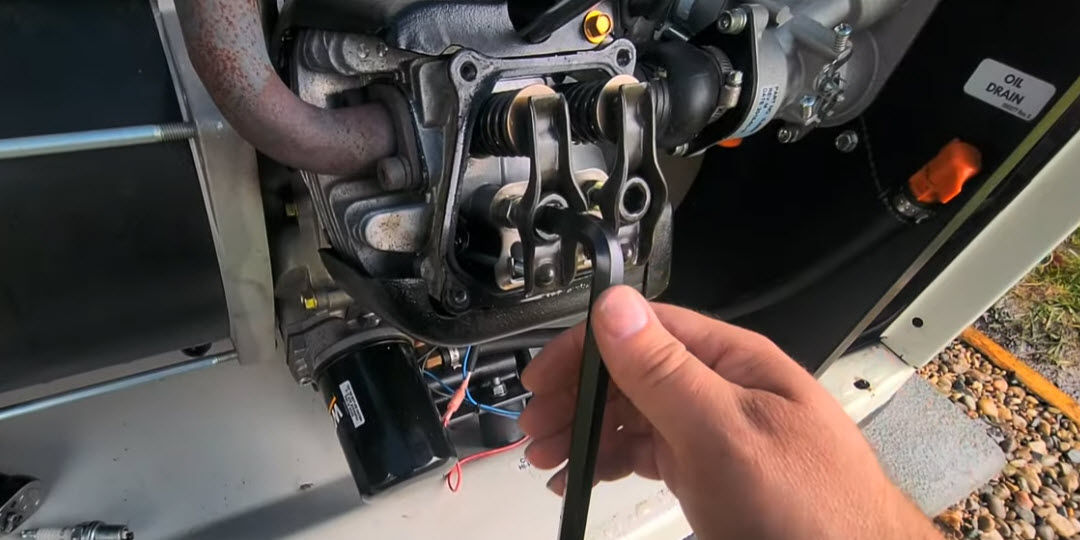

Inside your generator’s engine are small valves that open and close to let air in and exhaust out. For the engine to run properly, these valves must have the correct amount of spacing. Over time, heat and normal wear cause that spacing to change.

A valve adjustment resets this spacing back to factory specifications so the engine runs smoothly, efficiently, and reliably. This is a precise mechanical adjustment, not a visual check, and must be done carefully to ensure proper operation.

If valve clearances drift out of spec, performance and reliability suffer. Common issues include:

- Hard starting or no start conditions

- Rough running or misfires

- Loss of power under load

- Increased wear and overheating

- Shortened engine life

Is This a DIY Task?

This is why manufacturers recommend valve adjustments by a certified professional rather than a homeowner task. It's gIt can be a DIY task if you are comfortable with engines or a savvy DIY'er. Valve adjustments do require partial disassembly, precise measurements, knowledge, and the correct tools. Incorrect adjustments can cause more harm than good.

How Valve Adjustments Fit Into Proper Generator Care

Valve adjustments are not a standalone service. They are part of a comprehensive approach to keeping your generator reliable long term. Along with oil service, filter replacement, battery testing, and full system diagnostics, valve adjustments help ensure your generator starts quickly, carries load properly, and is ready when the power goes out.

Annual Maintenance Options

Valve adjustments can be performed as part of your annual maintenance by a certified Generac generator technician for a small additional feel while we are on-site. We will ensure critical engine tolerances are checked and corrected before they turn into performance issues or expensive repairs.

Routine maintenance is not just about keeping a generator running. It is about making sure it works exactly as expected when your home depends on it.

Hydraulic vs Manual Lifters

In internal combustion engines (including those found in generators), manual (solid) lifters are simple components that require periodic clearance adjustments, while hydraulic lifters use engine oil pressure to automatically self-adjust and eliminate clearance, resulting in lower maintenance.

How do I tell if I have Manual Valves?

Most Generac air-cooled generators before 2026 will have manual lifters that need periodic adjustment. Most Generac generators after 2026 (dubbed "NextGen") have hydraulic lifters. The best way to tell what you have is to check your owner's manual, look at the model's spec sheet, or contact us! Most Kohler generators have hydraulic lifters, but check your owners manual to be sure.

See Also:

Generac: How do I perform a valve adjustment on my air-cooled home standby generator?

VIDEO: Generac Valve Adjustment: The RIGHT Way Most Owners Never Learn (Step-by-Step)

VIDEO: Generac Generator 8kw-26Kw valve adjustment 5 minute completed.